Crowne Plaza | Membrane Roof Overlay

November 18, 2020

Client:

Crowne Plaza

Project Type:

Membrane Overlay

Project Length:

8 Months

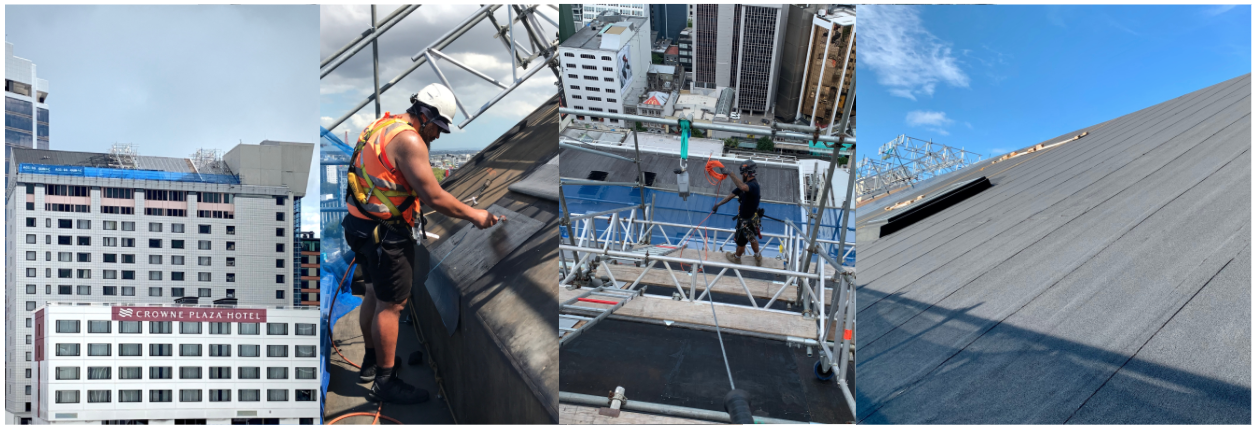

In 2020, Gunac | Waterproofing Specialists undertook a major roof overlay project on Crowne Plaza, in Auckland Central.

The existing roof was experiencing leaks due to the membrane reaching the end of its lifecycle. It was evident that the Crowne Plaza roof needed an upgrade. The Client sought out a contractor with proven experience in waterproofing to complete the necessary overlay works on this complicated roof.

Gunac | Waterproofing Specialists (an Access | Partners in Property company) have been in the industry for over 40 years. Gunac have waterproofed some of Auckland’s well-known buildings including the Viaduct Centre, Cordis Hotel and SkyCity Casino. Our Senior Quantity Surveyor, Dave Sheppard, took on this challenge, working hand in hand with the client’s engineer to develop a methodology and approach.

The pricing stage, undertaken over 2 years, involved meticulous planning with the Operations Team, Nuralite Waterproofing Ltd (Waterproofing supplier), Access Project Managers, subcontractors and Crowne Plaza. On acceptance, the delivery team were in full force ensuring the project was completed to succession.

Given the 34-degree roof angle, Gunac | Waterproofing Specialists had several measures put in place to ensure the health and safety of the workers, public and hotel staff. This involved;

- Ensuring all workers were trained & qualified in Working at Heights

- Installing a weather station to monitor wind speed, temperature & humidity. The weather radar was checked daily or hourly. The site was locked down & vacated when high winds, heavy rain or stormy weather was detected.

- Positioning a full-time Project Manager in the site office with 4x CCTV cameras recording 24 hours to ensure workers safety and all work was undertaken following health and safety protocols

- Installing a temporary roof safety system as the original was in very poor condition & unserviceable

- Installing suitable edge protection by abseiling to the B.M.U. rail with scrim for added drop risk protection. This was removable for extreme weather events

- Securing crash decks on ground level over pedestrian walkways. Where crash decks were not possible, setting up exclusion zones

- Assembling the roof scaffolding on the ground in an adjacent car park

- Lifting the Scaffolding using the helicopter to the roof in two sections then assembling it in position on the roof

- Ensuring each worker always had three connections. Double hook lanyard & retractable lanyard system was installed to ensure the safety of our team

- Positioning full-time industrial abseilers. Amin Ab Paykar & Zannah Rose Thornicroft were stationed on the roof when work was being carried out. The abseilers acted as immediate Rescue Support in the event of any slips, trips or falls, ensuring all workers safety. Amin was responsible for checking, maintaining & certifying the working at height equipment

- Meticulous planning in scaffold structure. The scaffolding was separated into two uses: a builder’s scaffold & a waterproofing scaffolding. These sections allowed the builders to move ahead and work near the roof surface and the waterproofers to lay the membrane and operate further away from the surface. The scaffolding was mobile (on wheels & was able to be moved backwards & forwards as the task dictated).

- Certifying the Scaffold structure on a weekly basis (Certified by Acrow)

- Ensuring all tools & materials were always tethered with cord lanyards and attached to technicians or structure when on roof.

On the 9th of February 2020, the project began. Acrow Scaffolding landed a bespoke A Frame scaffold structure onto the roof via Heli-flight. Prior to the flight, the Acrow team had worked closely with Access and Gunac constructing a mock-up of the roof and the scaffold to ensure the structure would perform as needed at the extreme height.

With the scaffold plan proven, the delivery team began works led by Project Manager, Bevan Dalgety. Gunac | Waterproofing Specialists made great progress on the roof, however in the month of March, the site was shut down due to Government issued Covid-19 Lockdown. Before shutting down, Gunac had ensured the site was safely secured and the roof was well protected during this period including organizing approved daily inspections. This was an unforeseen event and led to an extension in the program. In April, the lockdown was lifted, and our team were permitted to return to site. The H&S plan was re-written to incorporate COVID-19 19 protocols & team followed extra precautions during our remaining time on site. The Hotel was announced as an isolation facility which meant the team followed special protections including constructing isolated access corridors and exclusion zones, additional PPE and a site specific entry & exit plan for the duration of the project, ensuring no contact was made with hotel guests and staff.

The wetter months were approaching thereafter however, with careful monitoring and planning, our waterproofing technicians powered through. The membrane was applied using traditional methods. This meant each technician was rolling the membrane (safely screwed) down the slope of the roof, applying heat to bond the material to the substrate, for over 6 months.

The end of September saw the final completion of Crowne Plaza. The new roof now has a 20-year warranty on product. The project was a success despite the difficulty faced over the pitch, the height and the unforeseen challenges presented along the way.

“This is a huge achievement for Gunac | Waterproofing Specialists. The client is thrilled with the outcome. The project showcases our ability to complete the most challenging of projects and we look forward to the next one” – Pieter Botha | Operations Manager for Gunac Waterproofing Specialists.

A big congratulations to every individual involved in the Crowne Plaza Membrane overlay project.

Crowne Plaza Summary Video

Project Team

- Quantity Surveyor: Dave Sheppard

- Project Manager: Bevan Dalgety

- Health and Safety team: Kate Herbert, Callum Adamson and Daleen Claassen

- Contract Representatives: Pieter Botha and Michael Murray

- Help and Rescue Support: Amin Ab Paykar & Zannah Rose Thornicroft (Industrial Abseilers)

- Waterproofing Technicians: Billy Leiataua, Sili Leiataua, Jay Cardino and additional tech from H2Go

- Product Supplier: Nuralite Waterproofing Ltd

- Scaffolding: Acrow Scaffolding

- Demolition: Degree Builders

- Plumbing: Profile Plumbing

- Building Consultant: North Harbour Building Consultants

Talk to our expert Waterproofing Specialists about any waterproofing project you have in mind gunacsales@access.kiwi.nz or call us 09 525 5566